The course aims to teach students fundamental concepts of structural steel design and its principles using a project-based and modular teaching model. These concepts are discovered/taught through team projects; the students connect the theory to real-life problems.

The course covers the concepts of structural steel design, building codes, material properties of steel, Load and Resistance Factor Design (LRFD), Allowable Strength Design (ASD), design of bolted and welded connections, tension members, compression members, column buckling, beams, lateral-torsional buckling, beam-columns.

Project 1: Exploring Structural Steel Shapes

The aim of this project is to develop a better understanding of various structural steel shapes and their properties. As part of the first project, 3rd-year civil engineering students explored various structural steel shapes in different buildings of the Kadir Has Campus. They aimed to find 12 steel members of different cross-sectional shapes, including standard (e.g. IPE, HE, channels, angles, HSS, etc.) and built-up steel sections.

For each section, students provided the photo and indicated its location. They predicted the steel shape by measuring its dimensions. They discussed the member type (beam, column, truss, etc.) and the load the member carries (tension, compression, bending moment, etc.).

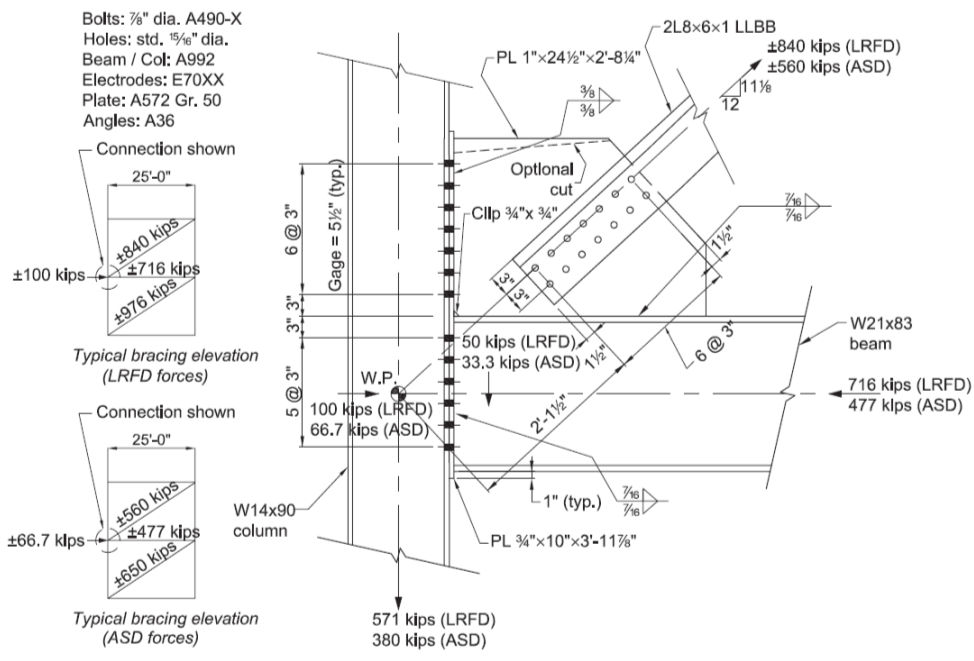

Project 2: Design of a Corner Brace Connection

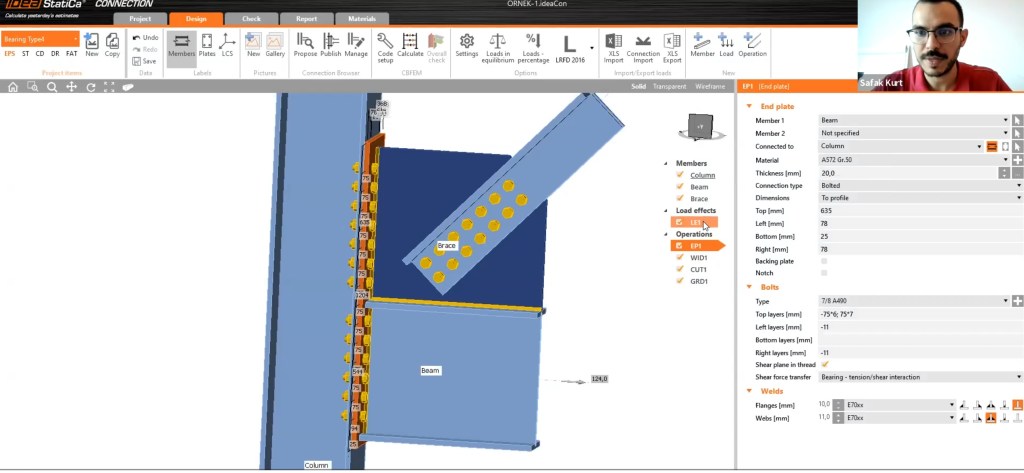

The aim of this project is to develop a better understanding of the design of structural steel connections and tension members with the use of commercial software, IDEA StatiCa.

The corner bracing connection shown in the figure below is designed based on AISC guidelines. The geometry, loads, listed members, and connection details are provided.

Students redesigned this connection according to Turkish standards and practice, assuming a similar braced frame with a 7.62 m bay width. Thus, they used equivalent European steel shapes and material properties, including for bolted and welded connections.

With the new design of the brace, gusset plate and its bolted connection, students modelled the whole corner connection in IDEA StatiCa platform.

Project 3: Industrial Steel Building – Analysis and Manual Design of the Roof Truss

The aim of this project is to practice tension and compression member design in steel roof trusses. In this project, students are to design the roof truss under the loads (dead, snow, wind) they computed in the Theory of Structures course. Using SAP2000 they computed the member forces for load and resistance factor design (LRFD) load combinations per TCDCSS 2018.

Later, according to TCDCSS 2018, they manually designed all the diagonal and vertical members. They used built-up double-angle sections of S235 steel. The angles were oriented back-to-back and connected with welded intermediate connector plates.

Project 4: Industrial Steel Building – Design of the Roof Truss Members and Purlins

In Project 3, students have designed manually diagonal and vertical members of the roof truss. Now, they are to design all the members, including top and bottom chords, using SAP2000. They need to compare manual calculations with SAP2000 and discuss the differences. In addition to tension and compression members of the roof truss, they are also to design the roof purlins.

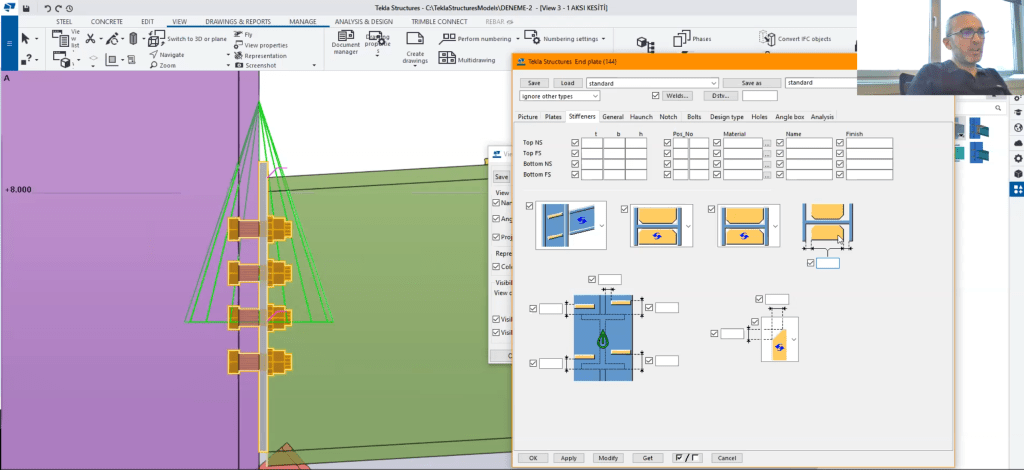

Students also attend an introductory online tutorial for Tekla Structures, a structural BIM software commonly used in steel projects.